Sidewinder Operation and Benefits

The Sidewinder tool is widely recognized for its exceptional productivity, operator comfort, and precise chemical placement within trees. This remarkable tool combines a power-operated drill with a hollow rotary self-sealing injector nozzle, boasting a patented design that sets it apart from the rest.

One of the key advantages of the Sidewinder tool is its adaptability to different farm machinery, thanks to its compatibility with a 12-volt drill. This means that farmers can use their existing equipment to power the tool, eliminating the need for additional power sources or specialized machinery. This convenience enhances efficiency and reduces costs.

To further boost efficiency, the Sidewinder tool offers electrically-activated compressed air-operated dosing pump models, enabling operators to use two injectors simultaneously. This feature allows for the treatment of multiple trees at once, saving time and reducing operator fatigue. By maximizing output and minimizing effort, the Sidewinder tool proves to be an invaluable asset.

Accurate chemical placement is crucial for effective tree treatment, and the Sidewinder tool excels in this regard. The power-operated drill creates precise entry points into trees, while the hollow rotary self-sealing injector nozzle ensures the chemical is delivered directly into the active xylem. This targeted delivery ensures that the chemical reaches the tree’s vascular system, where it can be distributed effectively to achieve the desired results.

In conclusion, the Sidewinder tool’s combination of a power-operated drill and a hollow rotary self-sealing injector nozzle offers outstanding productivity, operator comfort, and precise chemical placement within trees. Its compatibility with various farm machinery, ability to use multiple injectors simultaneously, and precise chemical delivery make it a reliable and efficient solution for chemical treatment in the forestry industry. Experience the power and effectiveness of the Sidewinder tool for optimal tree care.

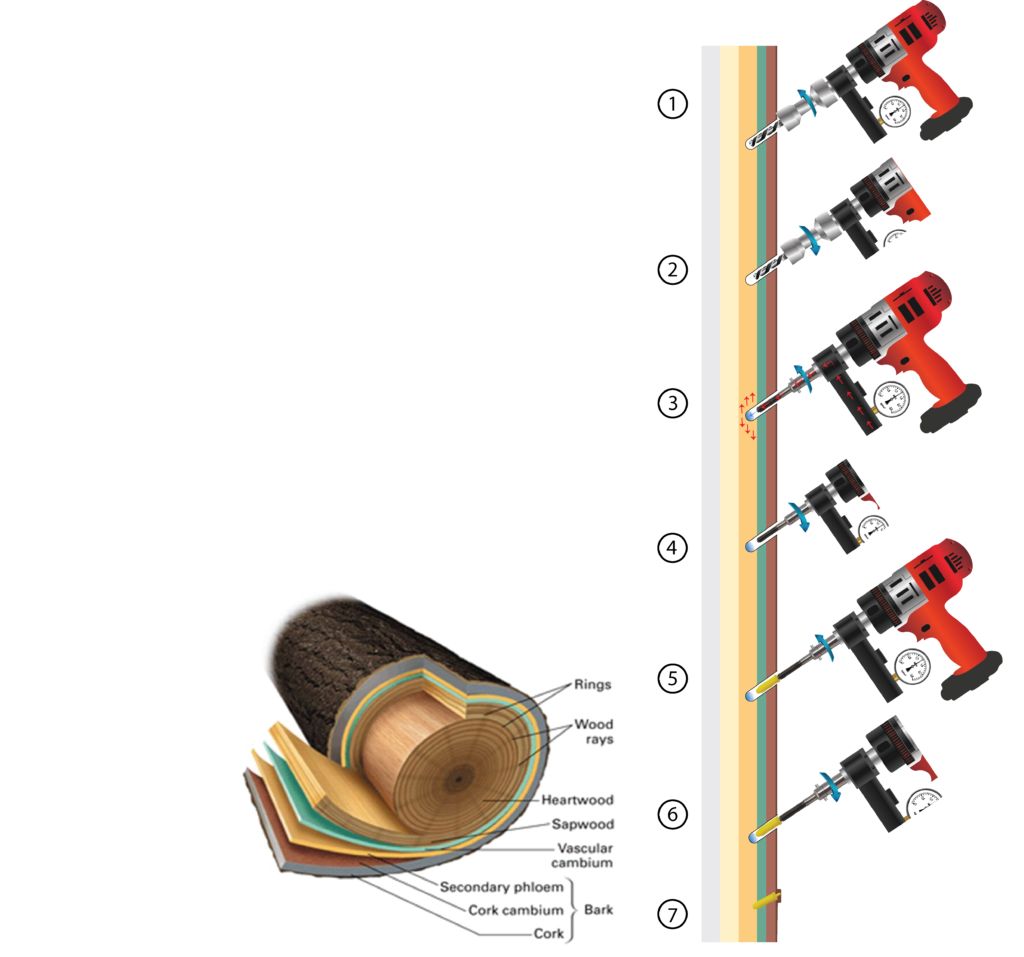

- Engage drill bit holder over nozzle

- Drill hole square on to tree surface in one continuous motion

- Standard drill bit 6 mm diameter x 40 mm long

- Dismount drill bit holder

- Screw nozzle into tree’s active xylem

- Activate dosing pump, multiple pump operation allow larger doses to be administered

- When pressure has dropped or the manual pump handle is right down, reverse drill and unscrew nozzle

- Place tip and drive lug of plastic sealing plug in slot in end of nozzle, place set drill control to “forward”

- Screw plug into tree leaving approx. 6 mm protruding

- Plugs will be totally over grown within 12 to 18 months depending on species and vigour of tree

- Different plug colours may be used to code the chemical used or the season of the injection